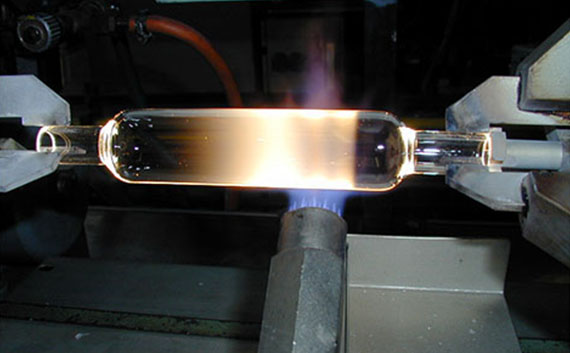

GRIFLAM® glass processing technology – our solutions to your glass processing challenges. The widest variety of tasks for processing glass and quartz glass can be safely mastered with our GRIFLAM® glass torch. As well as the high power of the torch, low a contamination through released particles is absolutely decisive. For this reason we also offer torches of stainless steel, chemically Nickel plated Copper and Silver.

Your advantages:

- Highest purity through minimum particle emission

- Individual consultancy and planning

- Layout of the complete gas supply system

- Application technicians for tests, commissioning and service

Areas of application:

- Glass processing

- Jewellery industry

- Glass fibre production

Contact

Messer Cutting Systems do Brasil Ltda.

Est. Mun. Do Varjão, 6500

Jardim Novo Horizonte

Jundiaí/SP - Brasil

CEP 13212-590

Rua Frei Pacífico, 71

Bairro São José

Caxias do Sul - RS

Brasil

CEP 95032-380

Glass Processing can be done by torches suitable for acetylene or hydrogen in combination with oxygen. Furthermore, torches for slow burning gases like propane, methane, MAPP or GRIESON in combination with oxygen are common. The product range also includes high power quartz glass melting torches up to 165 kW power. To prevent any pollution, torch heads can be made of stainless steel, chemically nickel plated copper or pure silver. Moreover, special lengths and designs can be supplied on request.

In our catalogue we present our entire GRIFLAM® standard program with over 750 high quality products.

We are sure that you will find innovative suggestions for your technical heating requirements in our GRIFLAM® catalogue.

Solution Modules

Messer Cutting Systems is the solution provider for the metalworking industry. In addition to cutting machines and oxyfuel technology, we offer software solutions, spare parts and a wide range of services.

We are sure that we will find the right solution for your individual requirements. Contact us, we will reply to you as fast as possible.