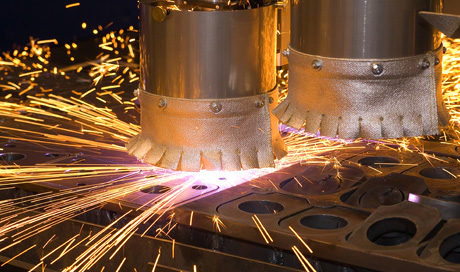

Plasma cutting was originally developed for the thermal cutting of materials which were unsuitable for flame cutting, such as high alloy steels or Aluminum. Today, the process is also used for the economical cutting of thin, low alloyed steels.

Characteristics:

- Plate thickness: 0,8 mm up to 160 mm

- Typical: 3 mm up to 75 mm

Key features:

- High to very high cut quality

- Smooth, cutting surfaces

- Metallurgical perfect surfaces for welding

- Medium heat input

- Excellent cutting speed

- Low harding on cutting surface

Cutting Options

Contact

Messer Cutting Systems do Brasil Ltda.

Est. Mun. Do Varjão, 6500

Jardim Novo Horizonte

Jundiaí/SP - Brasil

CEP 13212-590

Rua Frei Pacífico, 71

Bairro São José

Caxias do Sul - RS

Brasil

CEP 95032-380

Suitable Machines

MultiTherm® Eco

plasma straight

More